Industry Solutions

Industrial Processes

Extract the full potential from your industrial equipment with adaptive control.

Extract the full potential from your industrial equipment with adaptive control.

Industrial control systems undergo constant change, whether that's raw material inconsistencies, machine degradation over time or environmental changes.

Conventional control systems are inflexible, and therefore ineffective at dealing with variations. Today's factories require technology that responds to production data in real-time. Otherwise, productivity levels, product quality and sustainability efforts are all impacted.

Existing Al technologies struggle with the transition into physical hardware. In order to deal with the uncertainty, they require a large amount of training data and computational resources. The result? For those wanting an affordable, robust Al control system, most current Al options fall short.

Take effortless control of your manufacturing operations, by ensuring your system reacts and adapts to any changes in real-time.

Improve cycle times with higher control accuracy. Reduce wastage and rework, decrease time spent on machine setup and increased yield.

Improve product quality by ensuring consistent and reliable process outputs, achieve tighter tolerances and avoid costly scrap.

Reduce energy and resource usage. Lower emissions, reduce waste and accelerate your business towards its ESG commitments.

Repurpose equipment according to customer demand, and easily switch product grades as required. Invest in market growth, customer experience and new market expansion.

in energy efficiency

in compressed air usage

in temperature tolerance

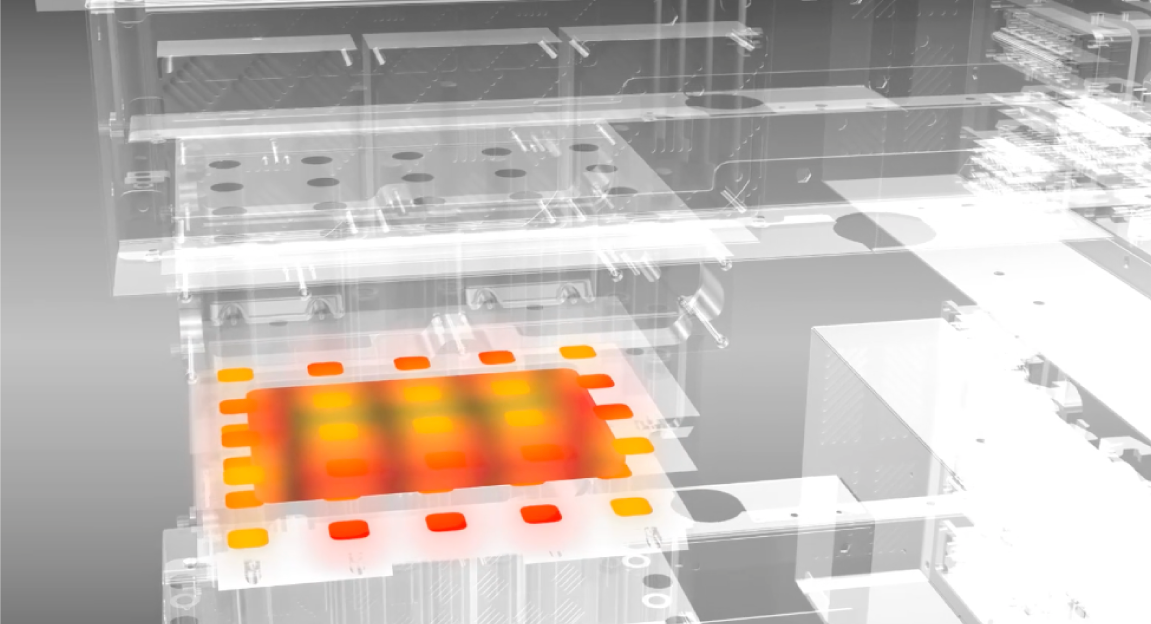

Adaptive control success for Surface Generationx

A world leading injection moulding and composites tooling OEM for the automotive and aerospace industries, Surface Generation produces best-in-class hardware for accurate tool face temperature control in thermal moulding applications.

A world leading injection moulding and composites tooling OEM for the automotive and aerospace industries, Surface Generation produces best-in-class hardware for accurate tool face temperature control in thermal moulding applications.

Surface Generation’s injection moulding operations are complex and non-linear, requiring an expert operator to frequently tune the control system. By implementing our adaptive technology, they were able to ensure better out of the box performance for new users. The AI controller allows the machine to consistently meet product tolerance parameters, whilst minimising energy consumption, all without the need of expert operator input.

Not only did we improve the system’s temperature tracking accuracy, but its robustness to variations in mould tooling, raw materials and the environment too.

Adaptive Control for Industrial Processes

To download the ebook, please submit form below