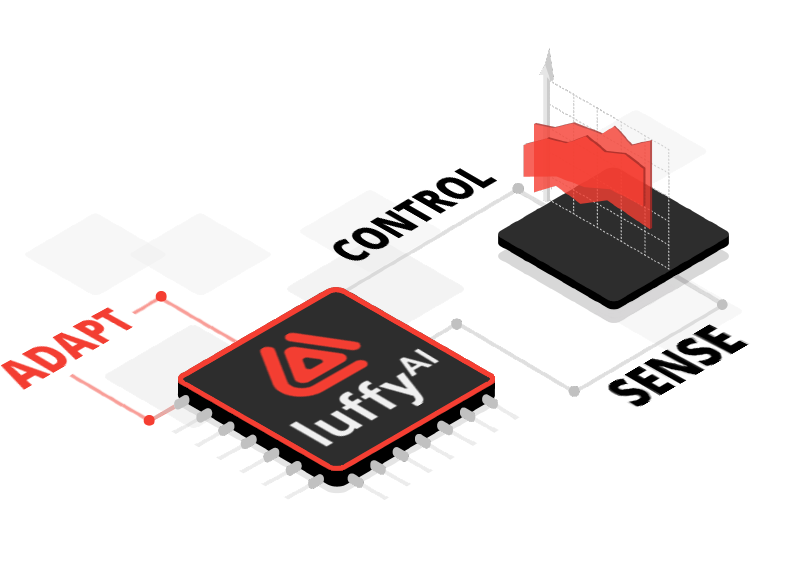

Adaptive

Intelligence

Al means Adaptable Intelligence. Just as nature evolves and adapts, we believe control systems should be always learning and adapting to what's happening around them. Here is how.

Al means Adaptable Intelligence. Just as nature evolves and adapts, we believe control systems should be always learning and adapting to what's happening around them. Here is how.

Luffy brings a radically new approach to control. Our adaptive Al technology is able to expand the operating envelope of your equipment. Adaptive Intelligence allows your system to be more resilient and robust when deployed in the field, and enables new modes of operation.

Our adaptive neural controllers can be a drop in replacement for your existing classic PID controllers or Deep Learning architecture. Our networks can be trained on a digital twin with a training curriculum that provides a degree of explainable Al, a key issue for the adoption of Al technologies. Modular architecture provides scalability and rapid deployment.

| Conventional AI | Classic Control (PID) |  |

|

|---|---|---|---|

| Suitable for control applications |  |

|

|

| Scalable to big control problems | Limited | - |  |

| Suitable for computing at the edge | - |  |

|

| Networks can transfer from simulation to reality | - | n/a |  |

| Explainable training curriculum | - | n/a |  |

| Continuous adaptation | - | - |  |

1. First, we develop a super efficient digital twin of your physical asset or process. This replicates your asset in a virtual environment, including its key features, functions and behaviours.

2. In this virtual environment, we develop and train our adaptive Al control, simulating thousands of scenarios, in order to truly expand the scope of your hardware's operation.

3. Running simulations for different scenarios, we validate the improved performance that our Al controller can bring to your process - ensuring we target your key value drivers.

4. Finally, when deployed, our cutting-edge robust Al algorithms continuously adapt at the edge, fine-tuning and optimising performance in the face of an ever-changing industrial environment.

in energy efficiency

in compressed air usage

in temperature tolerance

Adaptive control success for Surface Generationx

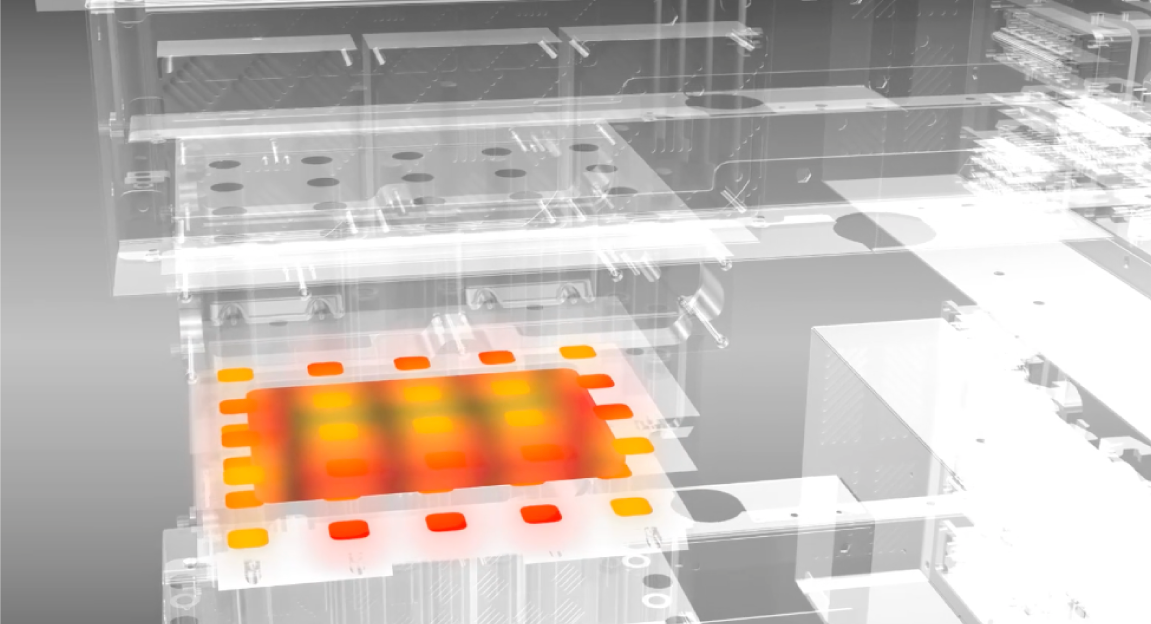

A world leading injection moulding and composites tooling OEM for the automotive and aerospace industries, Surface Generation produces best-in-class hardware for accurate tool face temperature control in thermal moulding applications.

A world leading injection moulding and composites tooling OEM for the automotive and aerospace industries, Surface Generation produces best-in-class hardware for accurate tool face temperature control in thermal moulding applications.

Surface Generation’s injection moulding operations are complex and non-linear, requiring an expert operator to frequently tune the control system. By implementing our adaptive technology, they were able to ensure better out of the box performance for new users. The AI controller allows the machine to consistently meet product tolerance parameters, whilst minimising energy consumption, all without the need of expert operator input.

Not only did we improve the system’s temperature tracking accuracy, but its robustness to variations in mould tooling, raw materials and the environment too.

We’re inspired by like-minded people who dare to be different and share our passion for innovation. Want to find out how you could be part of our mission to transform control?

Email info@luffy.ai, call 01865 590 850, or use the form below to get in touch.